For artists and collectors sponsored by Intercal...your mohair supplier and Johnna's Mohair Store

Thanks for any help you can offer. Hugs Ali x

Are you able to adjust the position of the needle? If your machine has zigzag, the opening in the throat plate should be wide enough so that adjusting the needle position should work. Just practice til you find the size seam you want. I use a quarter inch for most of my bears.

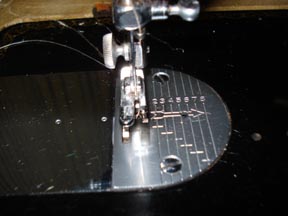

Hi! I'm not sure I understand the issue you are having. I use a 'general purpose' foot for nearly all my doll/plush sewing. It sort of looks like this. My machine is an old Bernina 830, for reference.

The foot is fairly wide and I just use different points on the foot to measure a seam allowance. When making my own patterns a make the seam allowance match the outside edge of the foot. On Japanese patterns the seam allowance tends to be narrower so I use the inside edge of the inner feed track as a guide.

I don't know if I'm making any sense...or if it even applies to other machines. ^_^;;; Basically, all I do is check the seam allowance against my machine and find a point on the machine I can use as a guide. The fabric almost never sticks out further than the width of the foot...though sometimes, if I'm struggling with a certain fabric, I'll widen the seam allowance for ease of sewing and trim it down later.

I have a Janome...I just use the basic foot that came fitted onto the machine...I have never had a problem with the seam width..some people mark the sewing line and follow that. I don't do that I just use the edge of the piece I am sewing as my guide ...if that makes sense!!

A zipper foot is also good for small width. Try that, although I am using a singer machine. Hope it helps

A zipper foot is also good for small width. Try that, although I am using a singer machine. Hope it helps

Thank you ladies for such a quick response :hug: I think I will get the machine out again (I put it into the garage in disgust :redface: ) and have another try. I might mark the sew line like you suggested Jenny just as a guideline and then I can see where I need to be in future. I do have a zipper foot (still sealed in its packet  , but I think I'll try the basic foot thats attached first - save messing about with machinery. I'm not confident on my machine (only use it for shortening hem lines). Any advice on which needles may be best for synthestics, I do trim my seam allowance before sewing?

, but I think I'll try the basic foot thats attached first - save messing about with machinery. I'm not confident on my machine (only use it for shortening hem lines). Any advice on which needles may be best for synthestics, I do trim my seam allowance before sewing?

Big hugs to you all, Ali xxx

I work with very thick synthetics. The only time I trim seams is when I'm sewing in the 1 inch across circle of a cat tail, it's just too thick without trimming. I never use a measured seam width. It depends on what I'm sewing and a gut feeling about what is needed. Head seams are narrower than body seams; tight corners call for narrower seam allowances. I guess because I design all my own patterns I automatically figure in my style of sewing and use of seam allowances. Try to relax and give yourself time to experiment  Find out what works for you and doesn't make you feel anxious so you can concentrate on your designs.

Find out what works for you and doesn't make you feel anxious so you can concentrate on your designs.

Karen

KJ Lyons Design

I use a #16 or #18 needle, this is an old Singer machine so I'm not sure these numbers will mean anything to you?

Hi Ali

I also have a Janome machine and the needle has 3 positions- centre, left and right. See if you can move the needle on your machine. The right hand position is 1/4 inches providing you put the edge of the foot against the edge of your fabric. Janome also has a 1/4 inch foot but I use this mainly for quilting.

Hugs

Gail

Hi Ali

Like Karen I too use an old Singer and the pressure foot is quite narrow in some of the older machines. I find the wider foot on newer machines do block your view. On my zig zag machine I also do what Gail suggested and that is move the needle to the right and line up my seam just outsite the width of the foot. With the narrow foot it is so much easier. And Karen is right, after awhile you get to "feel" your patterns and know just when to widen and when to narrow a seam. As far as trimming, I like to trim around the snout and chin area ...anywhere where you don't want the dreaded "rooster" comb to stick up. I like to use a #16 needle as well, it is sometimes referred to as a denim needle for sewing heavy weight fabrics. I do very little hand sewing as I like to stuff a head pretty full and hand sewn seams will always spread...at least mine do... good luck and the key to success is to have fun and relax. Never had a bear bite me for not sewing his seams perfectly