For artists and collectors sponsored by Intercal...your mohair supplier and Johnna's Mohair Store

Are they a good choice to use, or do the thread joints or plastic ones work better?

Hi,

It depends on the size and type of bear you are making. For some minis - thread jointing works best. My smallest mini is 3 3/4" though, so I use fiberboard joints in those.

All my larger bears I use either fiberboard or hardboard joints... whichever I have on hand.

Some people like the plastic joints in child safe bears in case they get wet.

Hope that helps!

yesh. and Since I have your attention, how about keeping heads on? I'm having a little bit of problems with the heads on the much larger bears staying on ._. have we got a cure for this?

When I first started I had a few heads pop off larger bears with the plastic joints as they can slip. Some plastic joints have better "grip or grooves" than others.

If you use screws or cotterpins that really can't happen. Then the only way to "loose your head" is if the gathering stitches break on the head or neck opening. Make sure to gather around the openings a few times to prevent this.

Hope this helps.

I use nuts and bolts with wood discs for the large heads, and I buy extra long bolts at the hardware store. took the discs in to check sizing. Then after they are on as tight as I can make them I cut the bolt excess off. It has the advantage, when cut off, of screwing up the threads so that there is no way the thing can ever unscrew itself----it may get loose, but its not going anywhere....I get all the hardware and discs from Intercal, in their economical large size quantity-except for the extra long bolts which, like I mentioned, come from the hardware store.

When i first started here 2 years ago I compared Intercal's pricing with the box stores and the local hardware store....Intercal had the costs beat down cold. So I stick with Intercal.

You don't have to be strong to use a good quality bolt cutters, they have this leverage thing going for them.

best wishes

dilu

You were reading my mind, Dilu! I was thinking I'd never be able to use bolt cutters!! Sounds like a job for super woman!!!

I have to agree... both US bear making suppliers are cheaper on joint hardware, even with shipping, than the local hardware stores and super stores!

I use the hardboard/fibreboard glued disks and cotter/T pins for smaller bears. I also lost a few heads in the beginning and making sure your stitches are tight around the joint is key. I usually go around twice just for reinforcement.

......Then the only way to "loose your head" is if the gathering stitches break on the head or neck opening. Make sure to gather around the openings a few times to prevent this.

For added strength, I also apply fray check all around the bolt (or cotterpin) after I have finished my stitching around the neck.

Reading all this was interesting as I am thinking of making my next bear a jointed one. However, I am wondering about those hardwood discs mentioned. Do they ever break? And using cotter pins, I am just not sure how this all works out. Any more suggestions on how to do the joints would really be appreciated. Rosie (contact@greatinfotips.com/teddyblog)

Hi Rosie,

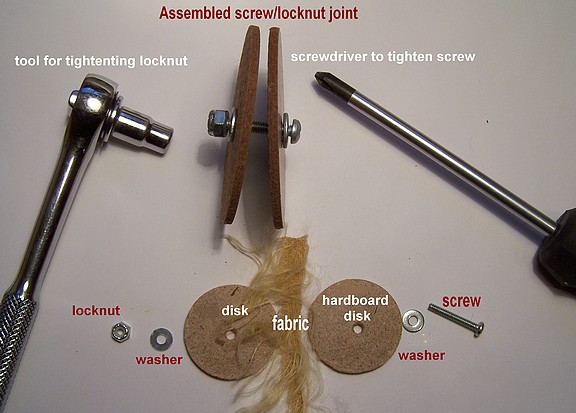

Here is a picture I took to show how to use the locknut & screws with hardboard disks. They are very strong and would be hard to break. You can replace the screw with a cotterpin and cullrthe ends of the pin like a snail on the inside of the arm/leg ,etc. (or curl like a crown joint -I'll look for a picture of that ) Hope this helps.

Hi Rosie,

Here is a picture I took to show how to use the locknut & screws with hardboard disks. They are very strong and would be hard to break. You can replace the screw with a cotterpin and cullrthe ends of the pin like a snail on the inside of the arm/leg ,etc. (or curl like a crown joint -I'll look for a picture of that ) Hope this helps.

oh wow. I love you . seriously. This is the image people should use in their books