For artists and collectors sponsored by Intercal...your mohair supplier and Johnna's Mohair Store

hello, just thought I'd share my first well second needlefelted critter, the first bunny didn't turn out as well

hello, just thought I'd share my first well second needlefelted critter, the first bunny didn't turn out as well  I can see how this becomes addicting! Any pointers or tips would be welcome

I can see how this becomes addicting! Any pointers or tips would be welcome

Hi Brenda,

You have done well, I wouldn't know where to start.

Keep going! Cannot wait to see your next attempt. :clap:

Love kayx.

thank you Kay  I didn't know where to start either so I had to buy a book and some tips from Mikki was most helpful

I didn't know where to start either so I had to buy a book and some tips from Mikki was most helpful  I think I'll put down the fur for a bit and practice more needlefelting. No pattern too is just great!!!

I think I'll put down the fur for a bit and practice more needlefelting. No pattern too is just great!!!

Wow, that's a cutie! I love needlefelting too, but it takes so much time...

thanks Shelli!  I have to admit my eyes get tired and I get a kink in my neck

I have to admit my eyes get tired and I get a kink in my neck  I used to do alot of cross stitch and fine detail painting quite a few years ago and I should be wearing glasses when I work but they make me feel sick

I used to do alot of cross stitch and fine detail painting quite a few years ago and I should be wearing glasses when I work but they make me feel sick

My glasses make me sick, too. I need them to drive or watch TV across the room, but when I try to read, they make me nauseous because farsightedness is setting in. At this point I can cure it by simply taking the stupid glasses OFF, but that only works for so long as I'm looking at stuff no farther than 2 feet away. AARGH!

In any case, your bunbun is darling, no matter what the visual struggle to finish him.

I sound just the opposite  I can watch tv and drive fine but when I read or do any up close detail work I need them. What's the word I'm looking for

I can watch tv and drive fine but when I read or do any up close detail work I need them. What's the word I'm looking for  you know like when you age you need bi focals? I'm just getting this sooner than the usual. I can read fine with them on and as soon as I look up at someone or something I want to puke

you know like when you age you need bi focals? I'm just getting this sooner than the usual. I can read fine with them on and as soon as I look up at someone or something I want to puke

Brenda, your bunny is very cute. Good job. I made a couple of needle felted animals and had just fun doing them. I don't have any tips as I just winged it. Be careful though, I have a pinched nerve in my neck/shoulder and I'm sure that all of the poking definitely had something to do with it. I hated to admit it, but have had to stop now until I heal up. Too bad, as I really loved doing it and it was so much fun seeing them come to life with every poke.

Peggy

Oh he is such a cute little bunny

What a very wonderful job you have done on this very sweet bunny Brenda. I love felting too, and it a nice relaxing change from stitching. I really like the whole process of preparing the raw wool, to carding. Watch out it gets addicting, I now have a large closet shelf full of wool. Glad you are having such fun. My only tip is that I have 4 different needles, large, medium, fine, and a star, I really have learned to use all of them on one piece, for different applications, try you will see, to me they do felt differently.

Joanne

How sweet, he has a really cute little face!

Thank you Peggy, Julia, Joanne, and Tami  I have large, medium, and fine needles and I hope the ones I ordered have star in them, better check. Finally received some nice colors of wool in the mail. Right now for the base I'm using the wool that's already spun and what a pain! but I have to get rid of it. I seem to sculpt better starting from a clump than I do if I felt onto a bear with a mohair muzzle, strange. Thanks for the tips

I have large, medium, and fine needles and I hope the ones I ordered have star in them, better check. Finally received some nice colors of wool in the mail. Right now for the base I'm using the wool that's already spun and what a pain! but I have to get rid of it. I seem to sculpt better starting from a clump than I do if I felt onto a bear with a mohair muzzle, strange. Thanks for the tips  always know where to go for good advice :hug:

always know where to go for good advice :hug:

Hi Breanda,

That is a very cute bunny and only your second try WOW! I find it hard to felt a solid sculpture. For me it is much easier to felt all the pieces and then thread joint them. The best tip I've found so far would be to steam the wool before you use it. It puts the crimp back in to the wool so it felts easier. To steam it I put a pot with about 1 inch of water on the stove and heat to a boil I have a little wire rack to cool cookies on that I set on top of the pot and lay my wool roving on it. The steam rises through the wool and the wool fluffs up to about twice the size. It only takes a minute or two. I've also read that you can wet the wool and microwave it to get the same results but I've never tried that. I hope I explained that clearly if you would like a picture to see what I mean let me know and I will take one. Have fun felting

Hugs Nichole

Nicole, do you do this after you have carded the wool. I have never heard of this technique, and I want to hear more

Joanne

oh yes more please  ALL tips are needed! and what's carding?? I'm making a squirrel right now and enjoying it can you tell? :dance: and thank you for the compliment Nicole :hug:

ALL tips are needed! and what's carding?? I'm making a squirrel right now and enjoying it can you tell? :dance: and thank you for the compliment Nicole :hug:

Carding is when you take the wool between two brushes and get it to go in the same direction, you card wool to blend different types or colors together, It makes it nice and fluffy, and easy to work with. For small amounts I use two large size slicker dog brushes. There are tutorials on the web if you look. You load the wool on one brush and then brush it onto the other one, back and forth. For large batches I use regular wool cards, they are like giant dog brushes. Even when I use prepared roving, I still brush it, to get it fluffy, works better for me that way.

Here is a great one on You Tube

http://www.youtube.com/watch?v=uhQcadvDO0o

Joanne

OK Here is some pictures

OK Here is some pictures

This is Merino wool roving before I do anything with it

Here is the merino before I steam it and after. Notice how it fluffs up. It's kind of hard to tell from the picture but the fibers are very straight in the first pile and they are very kinky and wavy in the second

Here is a closer look

I find that I usually don't need to card the wool when I do this because the steam fluffs it up for me. I usually only card when I am mixing colors. From what I under stand when they process wool into roving the fibers get straightened, when you steam it it goes back to a more natural crimped state. It is easier to felt with the crimped fiber because it tangles faster than straight fiber. Sorry the pictures are not better the batteries in my camera died as I was taking them. If you would like to see pictures of how I steam the wool I can take some tomorrow when I get new batteries.

-Nichole

I can see it just fine and can tell that it's quite a bit fluffier  and I get the carding now. I'm off to youtube to see the video

and I get the carding now. I'm off to youtube to see the video

I love your bunny Brenda

I am reading a "how to " needlefelting book at the moment as I would love to try needlefelting-it is just finding the time

Love all these extra hints and tips

Laurie :hug:

Thanks Nichole, I like this idea, I am going to try it. Pictures are great

Joanne

I saw your little rabbit and I was amazed - I would love to learn needlefelting and I hope I will find some help here on TT

I love all the bears with needlefelted paws or mouth - but I guess I will never do it

well I will keep on looking here and maybe some day I will try it out by myself

Anyway thank you for beeing a part here in your big family of TT :love:

Thank you! I never knew I would like it this much  and Andrea, there are soooo many wonderful artists here that are always willing to help

and Andrea, there are soooo many wonderful artists here that are always willing to help

I think you've done a marvelous job with your 2nd needle felting creation. I love the expression on the bunny's face. Looking forward to seeing more!

/bearhugs,

Looks good to me...

Kep up he good work

Carding & Combing have different purposes: 99.99% of the information that is currently online for both is for the age-old, traditional, spinning techniques.

The YouTube site that Joanne gave shows hand carding very well.

I share this link:

http://www.joyofhandspinning.com/hand-carding.shtml

as there are many images and videos on this site devoted to fiber for the many areas of preparation for the different end-results of spinning/knitting/weaving applications and are still useful for fiber prep for Needle Felting.

I have both Combs and Hand Cards in several sizes (and was teaching the use of pet grooming/flicker brushes as card substitutions, in the teddy bear world shortly after '00, when needle felting was just becoming a new feature of embellishing teddy bears and as well as designing whole work out of fiber) as well as now being on my second brand of drum carder.

In my own experiments, I find color blending much easier with Combs than with Cards, due to the way that the fiber transfers from one implement to the other: Combs being more random than Cards and so blending the color more thoroughly throughout without streaking, unless it's intentional. Many of the Combing sites show passing the moving Comb across the stationary comb in every direction. Without MUCH prior experience I would caution that it's best to use them at 90° angles to each other. That's the best way to evenly transfer the fiber from one Comb to the other.

COMBING:

This is the one of the best Combing technique sites I've seen, of hundreds & hundreds online -

http://www.youtube.com/watch?v=Ae6aZwsw … re=related

However, all of these sites are prepping fiber for spinning, which becomes yarn, which becomes fodder for weaving, knitting, crochet...

In needle felting we need both of these tools, cards and combs, for only their Beginning stage of work: to remove as much vm as possible, pull off the broken ends of the locks/staples and to BEGIN to straighten the fibers.

CARDING is usually worked after combing (or Flicking, when both are done by hand and Combing will not be preformed) and puts them into a semi-oriented (to each other) relationship while Combing makes them absolutely straight beside each other, leaving out the second cuts (made by the shearer and NOT appreciated by the animal's owner or the purchaser of the fleece!) and shorter lengths within the fleece.

The absolutely aligned fiber is called Top, and in spinning, these longest fibers are used to create Worsted fabric (Weaving) and Yarns (Knitting).

The Merino that you used for your project, Nichole, had 2 things that were fighting you:

1 -the micron or fineness/thinness of this breed's fiber and

2- the 'put-up'.

Commonly, put-ups are as

A - Top, also called Colonial Top (a blend of different breeds instead of just 1 breed)

B - Roving/Slyver(slī ver)/Pencil and

C - Batt.

- Top is the most straightened, longest fibers of each breed.

- All roving types are semi-straightened and batt is the least oriented, most matte-looking put up.

- Batt is actually the easiest to work with in needle felting, because with all of the fibers in an already very mixed up direction they most easily mix in with the neighboring fibers. The very smoothness of the Top fibers, even with some of their natural crimp/curl/wave returned through steaming, still don't mix (needle) in as easily because it's the ends that need to be pushed deeply into the mass and they are all laying parallel in rows, making it more difficult to impact most of them with the needle, Most needle felters don't put in enough hours of needling to send all of the ends into the mass to bond them well inside their structures.

As to the fineness, Merino is one of the finest/thinnest available. This is measured in terms of Microns and shown by the symbol of 'µ' - one millionth of a metre, or equivalently one thousandth of a millimeter. Most Merino averages about 16 microns; the medium micron Corriedale is about 30, much 'thicker' than Merino and therefore more easy to get the cuticle scales on the thicker fibers to grab onto each other and fill in the blank spaces between fibers. You can see that the finer microned Merino will take many more hours to needle it firmly and it will never give a rock hard structure but always remain somewhat flexible, however the fuzziness factor that others have to deal with as the final surface is being finished just isn't an issue with Merino.

Commonly, many needlers will begin by choosing a different fiber (larger micron number - meaning a thicker fiber breed) for the inner core or center of their project, keeping the project size in mind, (not picking a 6" long fiber for a 3" tall design) narrow their choices down further by choosing a breed with a medium micron size, to give the whole structure a solid, firm beginning and then go on to building with Merino/Cormo/Finn/Polwarth or any other of the very fine micron breeds for the fine details that these great breeds' fibers can allow you to build with.

All breeds have their own plusses and minusses!

From what I under stand when they process wool into roving the fibers get straightened, when you steam it it goes back to a more natural crimped state. It is easier to felt with the crimped fiber because it tangles faster than straight fiber.

Yes, when the fibers are drawn out/drafted, by hand or through a diz, from the Combs into a strand/ply of the desired thickness it's wound onto a niddy noddy (also seen on the Combing link above) and given time to allow the fibers to relax. While they are relaxing, as well as after removing from this tool, they can be weighted to help set the twist, before being plied together to make the yarn. This also helps to remove the natural curl/crimp/wave.

In commercial production, fabric and yarn are treated so that IF the end result product is treated as is recommended in subsequent use & cleaning the item will have a long life and NOT return to their natural crimp.

If not, - - well, we've all had a washing machine disaster with our favorite sweater.

That is Fulling - a whole other topic!

It is easier to felt with the crimped fiber because it tangles faster than straight fiber.

It's not so much the fact that it's more crimpy, though that certainly is true, but that the fibers are not laying in a straight line any longer, as Top is. The two ends that need to get driven into the mass as well as the middle sections of each fiber, in multiple places, are more available to be entangled with neighboring fibers, because they already do touch many many more different fibers than those of the Top put-up do, which touch a more limited number of fibers as they all lay in smooth parallel lines, but touching far fewer numbers of neighboring fibers; in this respect - part of your work is already done with Batt put-up. Mixing the fibers around with your fingers will never be as complete as is done commercially with Batt put-up. The multiple forms of Roving put-up land somewhere in-between: not totally smooth like Top, but not as random as Batt, so this is one more place that you have to choose your purchase of put-ups according to what your needs for working each project will be.

Those shiny, smooth, gorgeous, colorful ropes of (Top) fiber shown online are absolutely beguiling; who wouldn't want to hit the But-It-Now! button instead of the dull, non-lustrous colors shown for batts. But in the text above, I hope I've told you a little bit about why Top and all smoothly aligned fibers aren't always the best choice for needle felters, unless you are simply wrapping the fiber around a substructure and tucking in the ends with the needle. Then the Top put-up will work great. But it's not very handle-able, as the fibers aren't locked in to each other throughout the whole mass and are likely to come apart.

I've written elsewhere that if any fiber can be seen for more than half an inch without changing its direction it cannot be called firmly needle felted. And if it can be squeezed down in your fingers by more than 10% of its size, that too cannot be called firmly needle felted. Standards are being set every day in this newly blossoming field of endeavor; there is a place for every style of work, from the very softly worked projects, which are very good for seasonal design, which will be on display for a few weeks every year and in storage for the rest of the year, to the very very firm work. There often is no need to spend 3 weeks needling to rock hardness for this type of work, as the results will hold up nearly as well if not handled. If you'd like this to be a piece to be passed down to your grandies, then I too would put in the 3 weeks. Otherwise, consider it disposable, or recycle the fiber as decorating themes change in a few years.

But while the fiber is still in it's raw stage, it is possible to return some of its natural qualities. Here are my pictures of making use of a very long fiber, Coopworth, for a project I normally couldn't have used it for. And if you have made a few purchasing mistakes, I would certainly pull off a few wispy strips like this and put them over a low steamer and give them this treatment before working with them as they are or chalking up your purchase as a total loss and using them as packing material!

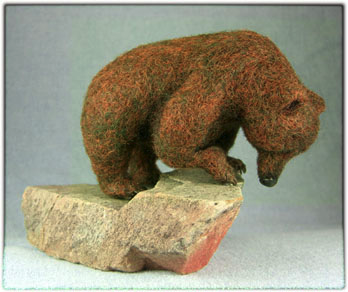

About 5 years ago I fell in love with some Coopworth fiber at a Fiber Fest weekend; it was a lovely Mahogany shade that I knew would make great Grizzly bears. Looking more closely at it, it's actually made up of a very almost-black-dark-green and dark red. Unfortunately, the camera sees the true colors - the eye actually sees the only blend so (and I really dislike this phrase but) - He really does look better in person!

It was a normal hot August and we were in our normal canning/freezing mode: corn, beans, peaches, etc... The more humid it gets the curlier my hair gets - and when I purchased the Coopworth in late July I remembered and anticipated this condition.

During the winter, when there is no humidity in in our heated homes, we keep an enameled canning kettle on a low simmer from November til April, to cut down on the static electricity. I return the natural curl to a lot of fiber I have stored then, since it doesn't inhibit the steam and it's like '2 birds with one stone'!!

I too used it in the same method as you Nichole, except I place the 3" tall plastic top we have to cover microwaved foods (looks like a large pie crust top) over the top to contain the steam and I steam each wispy batch for about 20 minutes.

Actually, the full action doesn't happen during the steaming but during the drying - the fiber doesn't look that much different right after steaming: I put the cake screens (I bought cheap used ones at the resale shops just for fiber) over the floor vents and they puff up during the drying. Don't touch the fiber after steaming even if the water has dripped on the fiber and it looks 'dented'!

The fiber shortens as well as crimps/waves/curls: I keep records of the amount for the samples I've already worked with for my manuscript. And there are at least half a dozen distinct types of 'curling' to sheep/goat/camelid fibers, I just cannot think of more than these 3 right words now.

My kettle is approx 14" across, cake rack is 24" long - IT FILLS IT WHEN PUFFED & DRY!! -

The next morning, after 20 mins steaming & overnight drying - Don't Touch after steaming!

Russel Rustles - 4" long Grizzly'

I find it hard to felt a solid sculpture.

This is explained by the nature of the fiber itself - Merino being at the very far end of the softest fibers. It has its place - such as for creating very small 1" items (though it's length might present problems - another whole subject) but your rabbit looked to be about 3" - 4" tall?

No matter how long you needle, even to the point of cutting or breaking the fibers, these fine micron fibers (Merino, Finn, Cormo, Polwarth, etc..) will never give you as firm a sculpture as other more Medium micron fibers. Knowing the fibers by name AND micron numbers - and demanding to know these from your retailer makes it important to them to find out just what it is that they are selling instead of just being a 'middleman', and why it's I choose to purchase from the small flock owners who raise their stock and know its qualities -

DON'T buy just WOOL - Find out WHAT you are buying or tell them you are going elsewhere! How else will you be able to find more if it's a fiber that really works well for your style of work, or worse, be able to avoid if it's a horror to work with for you?

There are far too many other sellers available to waste your $$ on these if they cannot get and relay this most basic info to you. Would you purchase anything else like this? 'A' tv? 'A' house? 'A' lawn mower? 'A' car? 'A' dress?

For me it is much easier to felt all the pieces and then thread joint them.

Have you ever experimented with getting the pieces to an 'almost finished stage', using some loose fiber as the 'glue' between the 2 pieces, needling them in deeply together from both pieces into each other, then using more fiber in small pieces (I never just wrap fiber around and around - as above: it doesn't give the needle enough ends to grab in the formed barbs to push into the other fibers through the joint and the 2 pieces being joined) to cover over this join of 2 pieces. Covering over this seam with enough fiber will eventually give a smooth profile line and not show where the join was.

This does create a Static Pose though; perhaps you do prefer to have a moveable joint. But one nice advantage that we have over the creators of fabric bears is that when pulling very tightly to thread joint, a divot is created on the outside of the limbs. We can simply cover that spot with a little more fiber and not worry about our jointing thread & knots showing!