For artists and collectors sponsored by Intercal...your mohair supplier and Johnna's Mohair Store

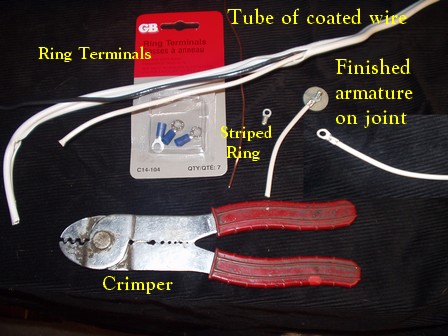

For those that are interested these are the tools I use to make my armatures. I use the method suggested in Nancy Tillberg's book 101 Bears To Make (pg 106). I buy the electrical wire at the hardware store off the big rolls that comes in different thicknesses. (This type had 3 plastic coated wires inside the plastic tube). I then bought Ring Terminals in the electrical section also - They are in the package and also come in different sizes.

For those that are interested these are the tools I use to make my armatures. I use the method suggested in Nancy Tillberg's book 101 Bears To Make (pg 106). I buy the electrical wire at the hardware store off the big rolls that comes in different thicknesses. (This type had 3 plastic coated wires inside the plastic tube). I then bought Ring Terminals in the electrical section also - They are in the package and also come in different sizes.

1) Strip the plastic off the ring terminal ( the blue part in this case) so it is then all silver with a round opening for the wire.

2) Insert the coated wire into the ring terminal.

3) Crimp ( squish) the ring terminal to secure the wire. - That red tool is a crimper. but pliers would work well too.

4) I cover the bottom end of the wire with tape so it doesn't poke thru the paw.

Sounds complicated but it is soooooo easy and soooooooo cheap !!!!!!

Tammy! You are awsome for posting this. I can't wait to try it.

Heather

Thanks Tammy! I just got supplies for making armatures and now it is all clear how to do it. Just one question. What kind of tape lasts as long as the bear will (hopefully) last? The regular clear office tape comes off after months or a few years.

Sabine

Hi Sabine, and welcome to the group !!! Your website bears are great. I see Nancy Tillberg's name by some does "Muster" mean pattern by Nancy ???

I do one of 2 things actually.

1) Electrical tape on the end. It's usually black and kind of stretchy.

OR

2) I pull the copper wire out of the plastic coating a bit before inserting it into the ring terminal. That leaves the plastic coating on the other end a little past the copper wire so it's not sharp.

I am by no means an expert and am just passing along what I've learned from Nancy. I suppose you could also trim some of the plastic coating off the end so the wire sticks out, then bend the wire in a loop so it isn't sharp. The main thing is to make sure the wire isn't sharp.

I hope this makes sense ?? I'll try to post a picture later today. My camera software seems doesn't seem to want to work at the moment :mad:

Good luck.

i use this same method that Tammy does. For tape , I use plummers tape..it is the stickest and strongest stuff around I know of...it is use in making doll armatures too...Winney

Makes perfect sense Tammy, thanks. You looked at my website, the first outside my circle of family and friends. Its only a few weeks old and I made it in German so my parents can understand it. I live in Sweden while they are still at home in Germany. I mean to make an English site, but bear making is more fun  And yes, 'Muster' is German for pattern, followed by the designer's name. I have used many commercial patterns, but also made a few of my own (like my avatar bear Barney). I'm not selling, just a hobby.

And yes, 'Muster' is German for pattern, followed by the designer's name. I have used many commercial patterns, but also made a few of my own (like my avatar bear Barney). I'm not selling, just a hobby.

Hugs

Sabine

Hi Tammy,

This was perfect timing for me, I just thought this morning that I would like to try armatures in my bears arms ..came along here and there was your message with a perfect photo  So I went straight along to the hardware store and found everything I needed except the ring terminal (will look elsewhere for that).... THANKS so much. It really helped me to know what I was looking for in the store, especially with everything in another language for me. I think people thought I was crazy going along all the electrical wires bending them to see if they kept their shape:P

So I went straight along to the hardware store and found everything I needed except the ring terminal (will look elsewhere for that).... THANKS so much. It really helped me to know what I was looking for in the store, especially with everything in another language for me. I think people thought I was crazy going along all the electrical wires bending them to see if they kept their shape:P

I also managed to find a bag of cotter pins - WAYYYY cheaper than buying from teddy stores... I'd rather save my money there and put it into buying scrummy mohair!

Bear Hugs,

Catherine

I am so happy to have found this!!!! I have been trying to figure out how to make my bears stand..and here's the answer..thank you SO MUCH for posting this Tammy!!!

Merry Christmas to all :)

doreen

My husband is an electrician and when the contractors are wiring a house there are always bits left over that are cut off....you may find a guy who wil save the leftover pieces for you! The wire that has three in it is called romex by the way. I've wired lots of homes over the years!!

I do this method too except at the ends in the paws I use needle nose pliers to bend the wire in a semi-tight loop then tape with electrical tape. This way if you like you can prewrap polyfill or wool around it before you stuff it down the arm or leg of your bear because sometimes it seems no matter how much you stuff the wire can be felt from the outside and I personally dont like to feel the wire, it kind of takes away the magic of the bear being able to bend and stand so sturdy. I also use the electrical tape at the joint site just where the wire terminal and wire are crimped together, because nothing is as frustrating as when your bear suddenly has an arm or leg that doesnt respond due to a joint that is not hooked to the wire anymore. Sometimes the crimper lets go because they are really not made to be moved around like we want a joint to move. Just a few notes from experience....  When I prewrap the paw part I just do a little enough to cover

When I prewrap the paw part I just do a little enough to cover

the wire so it cannot be felt from the outside, then stuff it inside the paw or foot.

Hi Tammy

I have been useing same method then i found some hair curlers there wired inside then covered in a soft sponge there great I just nick off the top and atatch the crimp you can buy them in all differesnt sizes a little more expensive than the plain wire but if you want to lesson the work load there just the thing and there very bendable

Hugs Paula